Bitchū Sōja, located in western Okayama Prefecture, is a place where the legends of Kibitsuhiko-no-Mikoto—said to be the model for the Momotarō tale—and the demon god Ura are still told. The ruins of Ura’s stronghold, Kinojō Castle, remain to this day.

With a sword museum in Sōja City, this region has preserved its sword-making culture since the Kamakura period. Bitchū Sōja Knives are masterpieces, forged by artisans who inherit this tradition, and craft each blade like a single Japanese sword.

SOJA HOUCHO

SOJA HOUCHO

Each knife is handcrafted individually by master swordsmiths using tamahagane—the same steel used for Japanese swords.

SOJA HOUCHO 真 –SHIN–

Crafted by swordsmiths and honed by master polishers, these knives are for those seeking something exceptional—closer in spirit to the Japanese sword.

At age 30, Tomioka Yoshimasa began his apprenticeship under master swordsmith Matsuba Kunimasa and joined the Japan Swordsmiths Association in 2019. The following year, he won the Newcomer’s Award at the Contemporary Swordsmith Exhibition—Japan’s premier event for Japanese swords. In 2023, he received the Special Prize at the same exhibition, and has since earned numerous accolades, continuing to demonstrate his skill as a swordsmith.

From a modern perspective, the making of Japanese swords appears inefficient and highly demanding. Yet by embracing this path without hesitation and forging the steel with his full dedication, Tomioka Yoshimasa discovers both the essence and pinnacle of Japanese craftsmanship. It is with this conviction that he dedicates himself to swordmaking each and every day.

TOMIOKA

YOSHIMASA

富岡慶正

TOMIOKA YOSHIMASA

After graduating from Tokyo Zokei University, Tomioka Yoshimasa initially worked as a web designer. In 2014, driven by the desire to ‘create something tangible with my own hands,’ he entered the world of swordsmithing—a field he had long admired. Applying his design experience to the craft, he has gone on to earn numerous awards. We asked this unconventional craftsman what thoughts he carries when standing at the forge.

This is his story.

Tamahagane: The Source of the Japanese Sword

Tamahagane is a rare steel produced through the tatara smelting method—a traditional iron-making technique preserved in Japan for over a thousand years. Today, production continues only at Nittōhō Tatara in Okuizumo, Shimane Prefecture. Iron sand and charcoal are continuously fed into the furnace for three days and nights to create this prized steel, known for its toughness and purity. It is an essential material for Japanese swords, praised as ‘unbreakable, unbending, and razor-sharp.’

Refining and Forging the Tamahagane

First, the heated tamahagane is hammered to consolidate the raw steel. Next, it is broken into smaller pieces, sorted, stacked, and returned to the forge, where the steel fuses together. The fused mass is reheated to burn off impurities, then powerfully hammered, flattened, scored, folded, and restacked. Repeating this process evens out the carbon content, producing a resilient steel with countless overlapping layers.

Forging the Shape of the Knife

The forged tamahagane is reheated in the forge and stretched out roughly. The tip of the knife is shaped first, then the body is drawn out. Finally, the red-hot steel is carefully hammered with a mallet, gradually refining the form of the knife from the edge outward.

The Quenching Process

After refining the knife’s shape and surface with files, tsuchioki—clay coating—is applied to the blade. This essential step determines the appearance of the hamon, the blade's artful temper line. The entire knife is then heated in the forge while carefully judging the temperature in the darkness. Once removed, the knife is plunged into water for rapid cooling. This quenching process, like tsuchioki, allows no second chances—it is the moment when life is breathed into the blade.

Polishing the Blade

The swordsmith performs a rough polish, checking the state of the knife and making fine adjustments to its form and thickness. The blade is then entrusted to a professional Japanese sword polisher, known as a togishi. With a delicate touch and refined skill, the polisher brings out the knife’s sharpness and beauty. Over many hours, working through a range of whetstones, the polisher enhances the blade’s luster—highlighting the hamon and grain to give the blade its distinctive brilliance.

Attaching the Handle and Inscribing the Name

The tang, or nakago, at the base of the blade is heated, ready for the handle to be fitted by hand. Finally comes the mei-kiri—the maker’s signature, engraved on the knife. Tomioka Yoshimasa carefully inscribes “Bitchū Yoshimasa,” kanji by kanji, marking the polished blade with his name. With this final step, ‘Katana Knives’ is complete.

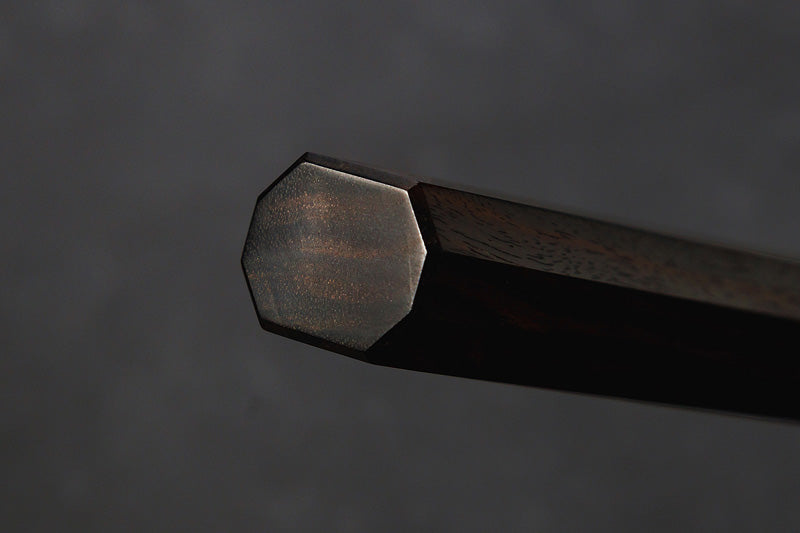

The handle of Katana Knives is made from the rare, premium wood Macassar Ebony. Hard and highly durable, polishing brings out its deep, lustrous shine. Its elegant grain shines in the seamless, ferrule-free design, naturally enhancing the blade’s beauty. The octagonal handle fits comfortably in the hand, providing a secure, slip-resistant grip, while a black resin ring adds a sophisticated accent.

A limited-edition knife sharpened by a professional Japanese sword polisher.

A knife that’s closer in spirit to a Japanese sword.

|

Japanese sword polishers, known as togishi, are master craftsmen responsible for the final touches of a sword. Even a blade forged with the smith’s full devotion has, at that stage, an indistinct form: the cross-section is unclear, the dark steel and white edge are not yet separated, and neither the hamon nor any luster can be seen.

Through the polisher’s masterful work, the body (ji), edge (ha), spine (mune), and tip (kissaki) are each refined in turn. As the process unfolds, the contrast between body and edge sharpens, the surface grain and hamon emerge beautifully, and the blade’s luster increases. In this way, the Japanese sword—regarded as the pinnacle of functional beauty—is born.

YASUI TAKAYUKI

At the age of 35, he returned to his hometown to live near his father, himself a sword polisher. This was the beginning of his path. He trained under his father as his master, while also learning much from fellow craftsmen. In 2009, he began his journey as a togishi in the world of sword polishing, where trust is the only true proof of skill.

Here, he shared his thoughts and the dedication that lie behind his work.

SOJA HOUCHO 真 –Shin–

Crafted by swordsmiths and honed by master polishers, these knives are for those seeking something exceptional—closer in spirit to the Japanese sword.